Product Description

Product Description

A10VSO18 A10VSO28 A10VSO45 A10VSO71 A10VSO100 A10VSO140 Hydraulic Spare Parts

POOCCA Axial piston pump A10V(S)O in swash plate design is used for hydrostatic transmissions in open loopcircuits. Flow is proportional to drive speed and displacement. By adjusting the position of the swashplate it is possible to smoothly vary theoutput flow of the pump.

POOCCA Axial piston variable pump A10VSO Series Size 10…140: CZPT A10VSO10, A10VSO18,A10VSO28, A10VSO45,

A10VSO71,A10VSO100,A10VSO140

Piston Pump Feature

-Variable pump with axial piston rotary group in swashplate design for hydrostatic drives in open circuit.

-The flow is proportional to the drive speed and displacement.

-The flow can be infinitely varied by adjusting the swash plate angle.

-2 drain ports

Excellent suction performance

-Low noise level

– Long service life

-Favorable power/weight ratio

-Versatile controller range

Short control time

-The through drive is suitable for adding gear pumps and axial piston pumps up to the same size, i.e., 100% through drive.

| SERIES | A10VSO/A10VO |

| MATERIAL | Cast Iron |

| DISPLACEMENT | 10/18/28/45/71/100/140cc |

| NOMINAL PRESSURE | 280 Bar |

| MAX PRESSURE | 350 Bar |

| MOQ | 1 |

A10VSO28,A10VSO45,A10VSO71,A10VSO100,A10VSO140 SERIES:

A10VO45DR/31L-VSC11N00 A10VSO71DFLR/31R-VPA42N00-S2709 A10V O 71 DFR1/31L

A10VO100DFLR/31R-PSC62K04 A10VO140DFLR/31R-PSD62K04 AA10VO180DR/32L-VSD22U24

A10VSO10DRG/52R-PSC64N00 A10VSO18DFR/31R-PUC12N00 A10VO28DRG/31R-PSC62K01

A10VO45DRG/31R-VSC12K68ESO545 AA10VSO71DFEO/31R-PPA12KB5 A10VO100DFLR/31R-PSC62N00 A10VO140DFLR/31R-PSD62K17SO294 AA10VO180DRF/32R-VSD22U15 AA10VSO10DFR/52R-PKC64N00-S1645 A10VSO18DFR/31L-PSC62K40 AA10VO28DFLR/31R-PSC12N00 AA10VO45DFR1/52L-VRC12K04

A10VSO71ED72/32R-VSB32U01P-S1550 A10VO100DFLR/31R-PUC62K01 A10VO140DFLR/31R-PSD62N00-SO160 A10VO180DRG/32R-VSB22U04 AA10VSO10DFR1/52R-VPA14N00E AA10VSO18DR/31R-VKC62K40

A10VO28DFR/31R-VSC62N00 A10VO45DFLR/31L-VSC61N00SO793 AA10VSO71DR/31R-PPA12O70 A10VO100DFLR/31R-PUC62N00 A10VO140DFLR/31R-VSD62K68 AA10VO180DRG/32R-VSD72U68E A10VSO10DFR1/52R-PUC64N00E AA10VSO18DFR1/31R-PRA12KB2-S1439 A10VO28DFLR/31R-PSC62K02 AA10VO45DR/52L-VSC64N00 AA10VSO71DFR1/31L-VPA42N00C A10VO100DFR/31L-PSC61N00

A10VO140DFR/31R-PSD62N00 AA10VO180DRG/32R-VSD72U99 AA10VSO10DR/52R-VKC64N00-S1768 A10VSO18DR/31L-PSC12K01 AA10VSO28DRG/31R-PSA12K52 AA10VO45DFR1/31R-PSC62K04-SO608 A10VO71DFLR/31R-PSC62K52 A10VO100DFR/31L-PSC62N00 A10VO140DFR1/31L-PSD62K02

A10VO180DRS/32L-VSD32U17-SO413 AA10VSO10DR/52L-VSC64N00 AA10VO18DRS/53R-VSC12N00-S4162

A10VO28DR/31R-PSC62K52 AA10VSO45DFR/31R-PPA12N00-SO23 AA10VO71DFR/31R-PSC62K68

A10VO100DFR/31R-PSC12K02 A10VO140DFR1/31R-PSD61N00 AA10VO180DRS/32L-VSD72U17-SO413 A10VSO10DR/52R-PUC64N00 AA10VSO18DFR1/31L-PPA12N00-SO239 AA10VO28DFR1/31R-PSC12N00-SO52

A10VSO45DR/31R-PPA12K26 AA10VO71DFR1/31R-PKC92K04 A10VO100DFR/31R-PSC62K01

A10VO140DFR1/31R-PSD62K01 AA10VO180DRS/32L-VSD72U99-SO413 AA10VSO10DRG/52R-VUC64N00-SO857 A10VSO18ED73/31R-PSC12K52T-S1069 AA10VSO28DFLR/31R-PSA12K52 AA10VSO45DFEO/31L-PPA12KB3 A10VO71DFLR/31L-PSC91N00 A10VO100DFR/31R-PSC62N00 A10VO140DFR1/31R-PSD62K02 A10VO180DRS/32R-VPB22U99 AA10VSO10DFR/52L-PKC64N00E AA10VSO18DFR/31R-PUC12K01-S1253 A10VSO28DFR/31R-VPA12N00 AA10VSO45DFR/31R-PPA12K54 AA10VSO71DFLR/31R-VPA42N00C A10VO100DFR/31R-PUC12N00 A10VO140DFR1/31R-PSD62K07 AA10VO180DRS/32R-VSB22U99-SO413 A10VSO10DFR/52R-PUC64N00 A10VSO18DR/31L-PUC12N00 A10VO28DR/31R-PSC62K01 -S1131 A10VO45ED71/52L-VSC11N00P-S5221

AA10VSO71DFEO/31R-PPA12K51 A10VO100DFR/31R-VSC62N00 A10VO140DFR1/31R-PSD62N00

AA10VO180DRS/32R-VSD11N00 A10VSO10DR/52R-PUC14N00 A10VSO18DFR1/31R-PSC62N00-SO108 AA10VO28DFR1/31R-PRC12K68-SO420 A10VO45DRG/31L-PUC62K01 AA10VSO71DFR1/31L-VSA12N00-SO32

A10VO100DFR/31R-VUC12N00 A10VO140DR/31L-PSD12N00 AA10VO180DRS/32R-VSD22U17

AA10VSO10DRG/52R-PUC14N00 A10VSO18DFEH/31R-PPA12KC1 AA10VO28DR/31L-PRC62K68

AA10VO45ED72/31R-VSC12K68P A10VO71DFR1/31R-PSC12N00-SO420 A10VO100DFR1/31L-PSC62K02

A10VO140DR/31R-PSD62N00 A10VO180DRS/32R-VSD22U99-S3189 AA10VSO10DR/52R-VSA14N00-S2380 A10VSO18DFR1/31R-PSC62K52 AA10VO28DFR1/31R-PSC62N00-SO52 A10VO45DFLR/31R-PSC12N00-681 A10VO71DFR1/31L-PSC61N00 A10VO100DFR1/31L-PSC62K07 A10VSO140DFLR/31R-PPB12N00

AA10VO180DRS/32R-VSD22U99-S3233 A10VSO10DR/52R-PKC64N00ESO858 AA10VO18DRS/53L-VSC11N00

AA10VO28DR/31R-PSC12K68-SO420 A10VO45DFR/31L-PSC62L10 AA10VSO71DFR1/31R-PPA12KB5-SO32 A10VO100DFR1/31L-PSC62N00 A10VSO140DFLR/31R-PPB12N00SO258 AA10VO180DRS/32R-VSD22U99-S3462 AA10VSO10DFR1/52L-PSC64N00 A10VSO18DR/31R-PPA12N00-SO239 A10VO28DR/31R-PSC12K01SO381 AA10VO45ED72/31R-PSC12K01-S1514 A10VSO71DR/31R-PPA42K68 A10VO100DFR1/31R-PSC12L33

A10VSO140DFLR/31R-PSB12N00 A10VO180DRS/32R-VSD32U00-S3883 AA10VSO10DR/52R-VKC64N00 AA10VO18DRF/53R-VSC12K52-SO413 A10VO28DFR1/31L-PSC62K01 AA10VSO45DFR1/31R-PSA12KB3-SO405 A10VSO71DFR1/31R-VPA42K68S1591 A10VO100DFR1/31R-PSC61N00 A10VSO140DFLR/31R-VPB12K01 AA10VO180DRS/32R-VSD32U99-SO413 AA10VSO10DR/52R-VKC64N00ESO858 AA10VSO18DFR1/31R-PPA12K01-SO128

AA10VO45DFR1/52R-VWC11N00-S2359 A10VSO71DRS /32R-VPB22U99S2183 A10VO100DFR1/31R-PSC62K01 A10VSO140DFLR/31R-VPB12KB4 AA10VO180DRS/32R-VSD61N00-S2636 AA10VSO10DFR1/52R-VSA14N00 AA10VSO18DR/31L-PSC62K01 AA10VO28DR/52R-PRC62K68 A10VSO28DRG/31R-PSA12K52

A10VO28DR/31R-PSC62K52 A10VO28DFR1/31R-PSC12N00-SO52 A10VSO28DFLR/31R-PSA12K52

A10VSO28DFR/31R-VPA12N00 A10VO28DR/31R-PSC62K01 -S1131 A10VO28DFR1/31R-PRC12K68-SO420 A10VO28DR/31L-PRC62K68 A10VO28DFR1/31R-PSC62N00-SO52 A10VO28DR/31R-PSC12K68-SO420

A10VO28DR/31R-PSC12K01SO381 A10VO28DFR1/31L-PSC62K01 A10VSO28DFEO/31R-PRA12KB3-SO479

A10VO28DR/52R-PRC62K68 A10VSO28DFEO/31L-PRC12N00 A10VO28DR/31R-PKC62N00

A10VSO28FE1/31R-PPA12N00 A10VSO28DFLR/31R-PPA12G80 A10VO28DR/31R-PSC62K01ES1743 A10VSO28DFLR/31R-PPA12N00 A10VO28DFR/31R-PSC12N00 A10VO28DFR/31R-PSC62K01

A10VO28DFLR/31R-PSC62K01-SO52 A10VSO28DFLR/31L-PPA12N00-SO160 A10VO28DFR/31R-PSC62N00 A10VO28DFR1/31R-PRC12K68 A10VO28DFR/31R-VSC62K68 A10VO28DR/31R-PSC62N00

A10VSO28DR/31R-PPA12N00 A10VSO28DFR1/31R-VPA12K02 A10VO28DFR1/31L-PSC12K01

A10VO28DFLR/31R-PSC62N00 A10VO28DR/52L-VSC64N00 A10VSO28DRG/31R-PSA12KB2

A10VSO28DFEO/31R-PRA12KD3-SO479 A10VSO28DR/31L-PPA12K01 A10VSO28DRG/31R-VPA12N00

A10VSO 18 DR/31R-PPA12N00 A10VSO 18 DRG/31R-PPA12N00 A10VSO 18 DFR/31R-PPA12N00

A10VSO 18DFR1/31R-PPA12N00 A10VSO 18 DFLR1/31R-PPA12N00

More Products

Company Profile

Our Advantages

1.Quick response within 12 hours

2.Accept small order(MOQ:1pcs)

3.Poocca make large inventory of all pumps parts,we can assembly pumps the moment you place the order with most competitive price.

4.Excellent after-sales service

5.Strict quality control system.100% factory testing and inspection personnel in accordance with international standards for the high-frequency sampling,to ensure the quality of products manufactured

Packaging & Shipping

Review

FAQ

Q:1.What’s your main application?

–Construction machinery

–Industrial vehicle

–Environmental sanitation equipment

–New Energy

–Industrial Application.

Q:2.What is the MOQ?

–MOQ:1pcs.

Q:3.Can I Mark My Own Brand On The Pump?

–Yes. Full order Can mark your brand and code.

Q:4.How long is your delivery time?

–Generally it is 2-3 days if the goods are in stock. or it is 7-15 days .if the goods are not in stock, it is according to

quantity.

Q:5.What payment method is accepted?

–T/T,L/C,Western union,Trade assurance,VISA

Q:6.How to Place your order ?

1).Tell us Model number ,quantity and other special requirements.

2).Proforma Invoice will be made and send for your approval.

3).Productions will be arranged upon receipt of your approval and payment or deposit.

4).Goods will be delivered as stated on the proforma invoice.

Q:7.What kind of inspection you can provide?

POOCCA has multiple tests from material purchasing to finished products by different departments, like QA, QC, sales

representative, to guarantee all pumps are in perfect condition before shipment. We also accept the inspection by the third party you appointed.

Axial Piston A10VSO A10VO Series Hydraulic Pump A10VSO71DFR/31R-PPA12K01

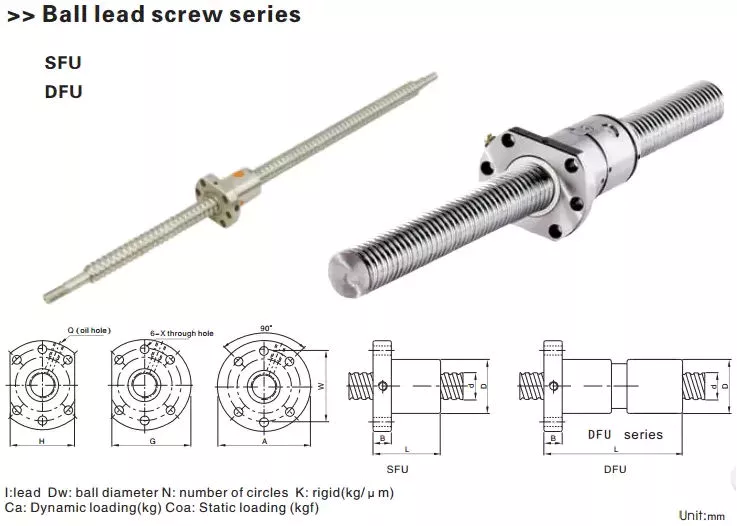

Specifying a Ball Screw

When you need a high-quality ball screw, it is important to select 1 with the proper dimensions and specifications. When you are looking for the best product, you should consider features such as preloading, surface finish, and internal return system. You can learn more about these features in this article. If you’re unsure which type of ball screw to select, contact a reputable supplier for further guidance. To find the best product for your needs, click here!

Brinelling

When specifying a Brinelling ball screw, it is crucial to know how much axial load it can safely bear. The static load capacity, which is given in the catalogue, applies only to pure axial loading, and any radial load that is smaller than 5% of the axial load won’t pose a problem. For more information, contact a CZPT engineer. Brinelling ball screw service life calculation should be performed using the following data:

Preload: The amount of load a ball screw can handle during a single revolution. Preload is the load applied before the ball screw starts moving, and the load is usually between 5 and 10 percent of the dynamic capacity. However, a ball screw that is subject to vibration will experience higher preload, requiring more frequent lubrication. The resulting mechanical stress may cause the ball screw to buckle, or cause the nut to re-circulate the balls.

Critical ball speed: The maximum speed at which the ball can move through the ball nut is called the critical ball speed. In contrast, running the ball screw at its critical shaft speed can lead to excessive vibrations, leading to premature failure of the end support bearings and brinelling of the ball track. Thus, it is recommended to operate a ball screw at a lower speed than the critical ball speed to prevent brinelling and plastic deformation of the balls.

False brinelling: False brinelling is a form of Fretting. False brinelling occurs when the bearings are not rotating. The movement will result in depressions or wear marks in the bearing raceway. This will cause noise, wear, and eventual fatigue. If these conditions persist, a newer ball screw should be used to test the system. The machine should be run for several hours and tested before replacing the bearing.

Preloading

The process of preloading ball screws minimizes backlash by applying pressure to the threads in the opposite direction of the screw’s direction of rotation. It prevents any movement of the screw relative to the nut. Various methods are used for preloading. A common 1 is to use oversized balls inside the ball nut. A double nut system may also be used. Both methods are equally effective. Regardless of the method used, the end result is the same – minimal backlash and increased efficiency.

In the conventional method of preloading ball screws, the motors operate simultaneously in opposite directions, causing them to have a relative motion of approximately equal magnitudes. This reduces the frictional resistance of the system, resulting in rapid traverse. The system is able to operate with minimal backlash during 110 inches of travel, reducing the heat developed by the drive nuts and the problems associated with ball screw heating. Moreover, this method can be used in a wide range of applications.

Another method of preloading ball screws is known as the ball-select method. This method includes the use of over-sized balls that force the balls into more contacts with the screw and nut than a normal ball screw. The advantage of this method is that it reduces backlash because the balls are not machined to high tolerances. The disadvantage of this method is that the ball screw will cost more to manufacture than a standard ball screw and nut.

A conventional design includes a mechanical mechanism that uses a series of balls to rotate a shaft. The problem of backlash is exacerbated by the mass of the shaft. The mechanical system is more complex than necessary and often requires a lot of effort. The present invention eliminates these problems by providing an improved method and apparatus for driving ball screws. This method provides a more efficient preload force that is dynamically adjustable while the mechanism is operating. The method can also improve friction and wear.

Internal return system

There are 2 different types of ball screws. The first type is external and the second is internal. The external type uses return tubes that protrude from the ball nut and extend above and around the outside of the screw. The internal type uses a single tube that spans the ball track, while the more common design uses multiple tubes spanning 1.5 to 3.5 ball tracks. The internal system involves a single return tube and several pickup fingers that guide the balls into the tubes.

The external return tube design is an easier, less expensive choice. The external ball return system has limited space but can handle a wide range of shaft diameters and leads. However, its physical size makes it incompatible with many high-speed applications. Therefore, careful consideration should be given to the mounting options. Internal ball return systems are best suited for small leads and ball sizes. Those that need a high speed will likely benefit from the external ball return system.

Internal ball screw technology has also kept pace with the demands of linear drive systems. Ball screw technology is now more durable than ever. Robust internal ball return systems circulate ball bearings through a solid pickup pin. These deflectors help the balls return to the screw in the correct location. They are crucial components in computer-controlled motion control systems and wire bonding. If you’re interested in the latest advances in linear screw technology, contact us today.

Ball screws are superior to lead screws in many ways. Ball screws are more efficient than lead screws, converting 90% of rotational motion into linear motion. As a result, they are more expensive than lead screws and acme screws. They also provide a smoother movement over the entire travel range. Furthermore, they require less power for the same performance. It’s no wonder that the ball screw is so popular in many different applications.

Surface finish

The surface finish of a ball screw is 1 of the key factors in determining the performance of the system. A ball screw with a good surface finish has superior performance in rolling resistance, backlash, and wear characteristics. However, it is critical to improve the surface finish of a ball screw to achieve precision movement, low wear, and low noise. To achieve this, special wire brushes will be used to polish precision-ground shafts.

For a ball screw to perform well, it must be hard, have a smooth surface, and retain lubricant. The surface finish of a ball screw should be smooth, free of cracks, and retain the lubricant well. Cracks and annealing are both undesirable during the manufacturing process, so a quality machine should be used for its surface finish. During the production process, a CBN cutting insert with full round or gothic arch profile can be used to achieve a high-quality surface finish.

Another finishing operation used in the manufacture of ball screws is lapping. Lapping improves surface quality and travel variation. It involves complex relative movements of abrasive particulates with the workpiece. This removes a thin layer of material from the workpiece, improving its surface quality and dimensional accuracy. The lapping process can be carried out under low-pressure conditions. It also enhances the friction torque and lubrication.

In lapping experiments, friction torque has the largest influence on travel variation and surface roughness. A friction torque of about 1 N x m is optimum. In addition, rotational speed has only a minimal effect. The best combination of these parameters is 1-1.5 N x m and 30 rpm. The minimum surface finish of a ball screw is around 800 mesh. The smallest variation in travel is observed at around half-way through the travel.

Lubrication

Proper lubrication of ball screw assemblies is critical to maintain optimum performance and life. Ball screw assemblies should be lubricated with grease, which is introduced directly into the ball nut. The lubrication port can be located at various locations on the product, including on the flange or in the external threads of the ball nut. Some ball nuts also feature a zerk fitting for easier lubrication.

The lubrication of ball screws is required in the case of operating conditions over 100oC. The minimum load for a ball screw is usually realized with a preload force. The lubricant is conveyed through the narrow lubrication gap due to the relative movement of the 2 surfaces. The increased viscosity of the lubricant enables separation of the contact surfaces. To avoid over-lubrication, it is important to check the lubricant level regularly.

The oil used in lubrication of ball screw assemblies can be either mineral or synthetic. The oil is composed of mineral or synthetic oil, additives, and a thickening agent, such as lithium or bentonite. Other thickening agents include lithium, barium complexes, or aluminum. The lubricant grade NLGI is a widely used classification for lubricating greases. It is not sufficient to choose a specific type of lubricant for a particular application, but it provides a qualitative measure.

Despite being essential to the performance of a ball screw, lubrication is also essential to its lifespan. Different types of lubricant offer corrosion protection. Before using a lubricant, make sure to thoroughly clean and dry the ball screw. If there is any buildup of dirt, it may damage the screw. To prevent this from occurring, you can use a solvent or lint-free cloth. Lubrication of ball screw assemblies can greatly extend the life of the assembly.