Product Description

QS MACHINERY Gravity Die Casting Machine Manufacturers Customized Steel Casting Service China High Precision Steel Casting Parts For Agricultural Machinery

Product Introduction

Steel Castings Are Parts Or Pieces Obtained By Casting Molten Steel Into A Mold Using Molten Steel. It Is Manufactured Through A Casting Process And Is Usually Used To Manufacture Parts That Require High Strength, High Wear Resistance, High-Temperature Resistance, Or Complex Shapes.

Characteristics Of Steel Castings

High Strength:

Steel Is A Stronger Material, So Steel Castings Have Higher Strength And Durability.

Wear Resistance:

Steel Castings Generally Have Good Wear Resistance And Can Be Used In Heavy Loads And High-Speed Friction Environments.

High Temperature Resistance:

Steel Castings Generally Maintain Stable Performance In High-Temperature Environments And Are Not Prone To Deformation Or Melting.

Complex Shapes:

The Casting Process Can Produce Steel Castings With Various Complex Shapes To Meet Different Engineering Needs.

Plasticity:

Steel Castings Can Be Processed And Material Properties Modified Through Processes Such As Melting, Casting, And Heat Treatment.

Our Service

HangZhou QS Machinery Provides “ONE-STOP” Convenience. We Offer A Number Of Optional Finishing Services Added To The Steel Casting Parts That Provide More Value And Save Time.

HangZhou QS Machinery provides steel Castings From 0.1 Kgs To 80 Kgs, Within Various materials of Carbon Steel, Low Alloy Steel, and Grey Iron For Seed Drills, Rotary Tillers, Mulchers, Cultivators, And Precision Planters.

1. Steel Casting parts For Agricultural Machinery

We Combine Our Special Technology Of Lost Wax Casting Production With The Function Of The Real Parts And Help The Customer To Design The Parts Better Way, Help The Customer weld parts To Steel Casting Parts Lost Wax Casting Process, And Help the Customer Optimize The Design Of Steel Casting Parts Make Joint Efforts To Choose The Best Material And Best Production Technology For The Parts. We Get The Most Reasonable Design For Efficient Production, That Is Win-Win.

2. Steel Casting Parts For Construction Machinery Parts

HangZhou QS Machinery Provides Steel Castings With Wearable Material In Very Strong Mechanical Performance.

Those Steel Casting Parts Cover All Kind Of Drilling Head And Drill Bit With Wearable Alloy Steel Such As 35CrMoNi And 42CrMo4, And Cover All Kind Of Bracket And Support Arms In High Tensile Strength Steel.

3. Stainless Steel Castings

Stainless Steel Castings Are Cast Parts Made Of Stainless Steel Materials. Stainless Steel Is A Special Steel With Corrosion Resistance, In Which The Main Alloying Element Is Chromium.

Stainless Steel Castings Have Similar Characteristics To Ordinary Steel Castings, But They Also Have Unique Properties Such As Rust Resistance, Corrosion Resistance, And High-Temperature Resistance.

4. Alloy Steel Castings

Alloy Steel Castings Are Cast Parts Made Of Alloy Steel Materials. Alloy Steel Is A Type Of Steel Whose Properties And Characteristics Are Improved By Adding Other Alloying Elements To Ordinary Carbon Steel.

Alloying Elements Can Include Chromium, Molybdenum, Nickel, Vanadium, Titanium, Etc.

Steel Casting Processing Process

1. Design And Mold Making

2. Smelting And Pouring

3. Cooling And Solidification

4. Demolding And Trimming

5. Heat Treatment

6. Machining

7. Surface Treatment

8. Inspection And Testing

Related Products

Product Parameters

| Product Name | Casting Steel |

| Keywords | SteelCasting Part |

| Material | Carbon Steel, Low Alloy Steel, etc |

| Producing Process | Precision, Investment, Lost Wax Casting Or Customize |

| Design | As per the customer’s Design |

| Size | Customer’s 3D Drawing |

| Tolerance | Strictly Casting Tolerance |

| Dimensions | Customized Dimension |

| Quality Control | 100%Inspection |

| Product Certification | Both Material And Dimension Report |

| QC | 100% Strict Inspection For Every process |

| MOQ | 100 |

| Accept | OEM Service |

| Application | Farm Machinery Parts |

| One-Stop Service | Yes |

| Casting Production Equipment List | |||||

| Type | Description | Unit | Quantity | Status | Location |

| Wax Injection | Wax Beating Machine | Set | 8 | Using | Wax Injection Workshop |

| Wax Injection Machine | Set | 12 | Using | Wax Injection Workshop | |

| Wax Container | Set | 4 | Using | Wax Injection Workshop | |

| Shell Making | Dirt Catcher | Set | 1 | Using | Shell Shop |

| Sodium Silicate Beater | Set | 1 | Using | Shell Shop | |

| Lining And Shell Beater | Set | 8 | Using | Shell Shop | |

| Automatic CZPT And Shellproduction Line | Set | 1 | Using | Shell Shop | |

| Sand Spreader | Set | 1 | Using | Shell Shop | |

| Dex Wax | Lost Wax Equipment | Set | 2 | Using | De Wax Shop |

| Natural Gas Boiler | Set | 1 | Using | De Wax Shop | |

| Melting | Calc In At Or | Set | 1 | Using | Melting Shop |

| Bag-Type Dust Collector | Set | 1 | Using | Melting Shop | |

| Environmental Protectiondust Removing Equipment | Set | 1 | Using | Melt Shop | |

| Intermediate Frequency Induction Furnace | Set | 4 | Using | Melt Shop | |

| Casting Auxilary Equipment | Set | 1 | Using | Melt Shop | |

| Grinding | Activated environmental protection equipment | Set | 1 | Using | Backend Workshop |

| Apron Types Hot Blasting machine | Set | 4 | Using | Backend Workshop | |

| Dirt Catcher | Set | 2 | Using | Backend Workshop | |

| Grinding Machine | Set | 2 | Using | Backend Workshop | |

| Warehouse | Hydraulic Baling Press | Set | 1 | Using | Warehouse |

| Gas Supply | Natural Gas Storage Tanks | Set | 1 | Using | Lawn |

| Machining Equipment List | |||||

| Type | Description | Unit | Quantity | Status | Location |

| CNC | CNC Machining Center | Set | 4 | Using | CMC Area |

| Milling Machine | Universal Milling Machine | Set | 2 | Using | Milling Area |

| Vertical Milling Machine | Set | 4 | Using | Milling Area | |

| Lathe | Plain Lathe | Set | 6 | Using | Lathe Area |

| CNC Lathe | Set | 12 | Using | Lathe Area | |

| Hydraulic | Hydraulic Press Machine | Set | 6 | Using | Cold Correction Area |

| Hydraulic Riveter | Set | 1 | Using | Cold Correction Area | |

| Drilling | Vertical Drilling Machine | Set | 30 | Using | Drilling Area |

| Main Inspect In Equipment Used | |||||

| Type | Description | Unit | Quantity | Status | Location |

| chemical composition | Spectrometer | Set | 2 | Using | Inspection Room |

| Mechanical Property | Metallographic Microscope | Set | 1 | Using | Inspection Room |

| Tensile Testing Machine | Set | 1 | Using | Inspection Room | |

| Impact Testing Machine | Set | 1 | Using | Inspection Room | |

| Hardness Tester | Set | 3 | Using | Inspection Room | |

| Dimensional Test | Three-CoordinatesMeasuring Machine | Set | 1 | Using | Inspection Room |

| Nondestructive Examination | Magnetic Particle TestingMachine | Set | 1 | Using | Inspection Room |

| Dye Pan At Rant Testing Line | Set | 1 | Using | Inspection Room | |

| Projection Machine | Set | 1 | Outsource | Cooperated With CAEP | |

| X-Ray | Set | 1 | Outsource | Cooperated With CAEP | |

| Un Tra Sonic Flaw Machine | Set | 1 | Outsource | Cooperated With CAEP | |

Detailed Photos

FAQ

Q1. Are You A Factory Or Trade Company?

A: We Are A Factory With Over 20 Years In Casting, Forging, Fabrication And Machining. We Service Customers In Various Fields Such As Mining, Agriculture, Car Parts, Etc.

Q2. How To Quote?

A: Received The Sample Or Drawing, Then We Will Make The Quotation.

Q3. How About The MOQ?

A: Depend On The Weight And Material, If It Is Our Daily Melting Material, There Is No MOQ.

Q4.Delivery Time

A: Standard Or Customized Will Both Be Available.

Q5. How About The Packing?

A: Standard Or Customized Will Both Be Available. We Will Consider The Transfer At the Warehouse And Time Anti Rust During On The Sea.

| Casting Method: | Sand Casting |

|---|---|

| Casting Form Material: | Metal |

| Casting Metal: | Cast Steel |

| Casting Form Usage Count: | Semi-permanent |

| Surface Treatment: | Electroplating |

| Surface Roughness: | Ra0.1 |

| Samples: |

US$ 2.5/kg

1 kg(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Agricultural Parts and Implements Are Manufactured Using Steel

Agricultural parts and implements are manufactured using various metals, such as Steel. These metals are used for the purposes of agricultural machinery, as they are the strongest and the most durable metals. Steel is also a good material for agricultural implements as it does not rust, even in the toughest conditions.

Steel is the best metal for agricultural implements

Whether it’s a tractor, plow or any other agricultural implement, the best metal to use is steel. It is tough, durable, and affordable. Plus, it’s also eco-friendly. Steel is available in various grades and sizes, so it can be customized to meet specific performance characteristics.

Agricultural equipment is exposed to a lot of environmental factors, such as dirt, moisture, and harsh chemicals. It’s also frequently exposed to high temperatures. It needs to be made from materials that can withstand harsh weather.

Steel is a durable and malleable alloy that can be manufactured in different grades and sizes. It’s also available in different thicknesses, so it can be used for various applications.

Steel can be used for agricultural equipment because it’s highly resistant to corrosion. It’s also easy to clean and maintain. Plus, it’s 100% recyclable. Steel can be used for animal pens, trailers, fencing, and even tools.

Galvanized steel is a metal commonly used in agricultural tools. It has a zinc coating that prevents corrosion. It’s also self-healing and has a lower maintenance cost than other coated metals. It can also be used for irrigation systems, tractor parts, and animal pens.

Agricultural machinery is continuously being improved to ensure efficiency and comfort for its users. This includes the development of innovative technologies. For example, manufacturers develop structural steel shells and solid steel frames for tractors. These components are designed to work together, enabling farmers to harvest more crops per acre without having to refuel.

Modern farming operations require larger and more automated equipment. They need to be built with materials that can withstand the rigors of a farming environment. Agricultural equipment is made from a variety of steels that are tough and durable. Steel also provides corrosion protection and durability.

Whether you are looking for a metal building, an irrigation system, or a tractor part, you’ll find the best metal for agricultural implements at CZPT Company. The company can provide you with all the steel you need, including metal processing and fabrication services.

In addition to being a versatile metal, steel is also a cost-effective and environmentally-friendly option. Using steel in your agricultural machinery allows you to produce higher crops per acre without compromising durability. It’s also lighter than conventional steel, meaning your equipment will need less fuel.

Changes in agricultural plots

Getting a good look at the latest data is a must to fully grasp the state of the union. Thankfully, our partners at PwC can help you uncover the secrets of the world’s most productive agricultural region. In a nutshell, we can help you map out a comprehensive and robust plan for the future of the agricultural industry. By leveraging our expertise in land characterization, land management and planning, we can ensure your property is in tip-top shape for generations to come. Lastly, we can help you secure financing for your agricultural projects, while ensuring your investment is rewarded with the highest possible rates of return. No matter what your needs are, PwC will help you achieve your goals. Our experts are armed with the latest technology and the expertise to ensure your next land acquisition will be a smooth and stress-free experience. We will also be on hand to provide ongoing guidance as you engage in a land-related decision making endeavor. Your PwC experts can assist you on a personal level, or through an organization. For more information, contact your local PwC office today. Besides, we would be happy to help you in any way we can. If you are a landowner or landholder in need of advice or assistance, please do not hesitate to contact your PwC expert for a free, no obligation consultation.

High demand for OEM parts

Agricultural machinery OEM parts are rapidly growing at a rate of 3.6% per year. This growth is mainly driven by increased global food demand and rapid crop production. However, the volatility in commodity prices and deteriorating raw material prices are stymieing market growth.

The high demand for OEM agricultural parts is mainly due to advancements in technology. These technologies are improving the economic situation of the farmers. They are also driving interest in agricultural machinery.

Agricultural equipment is a significant investment. It is important that parts for the equipment don’t cost more than they need to. This means that manufacturers and dealers need to focus on providing quality replacement parts. OEM parts are a great way to ensure that you are getting the performance that you need from your equipment.

The agricultural machinery OEM market is a highly competitive market. The major OEM firms will dominate the market in the future. Manufacturers are working to provide new solutions to the agricultural industry. These new solutions include heavy equipment OEMs that are providing innovative solutions for agriculture.

The OEM parts are not only good quality, but they come with a warranty as well. This warranty ensures that the parts will last longer. They also come with a variety of parts that you may not be able to find elsewhere.

OEMs provide a great return on investment to their business partners. They have years of experience building specialty products. They are also able to quickly turn around requests. However, they have limited availability. OEM parts are expensive.

Aftermarket parts have been around for many years, but they have become popular in recent years. The low price makes them a good choice for many customers. However, there is still debate over whether OEM parts or aftermarket parts are the best option.

Aftermarket parts are a good alternative, but they may not perform at the same level as OEM parts. They may also use more expensive materials. The downside to aftermarket parts is that they may not carry the brand name that you are looking for.

When you need agricultural equipment parts, make sure that they provide the performance you are looking for. OEM parts provide a higher level of performance than aftermarket parts, but they are also much more expensive.

editor by CX 2023-11-23

China manufacturer OEM Sheet Metal Custom Stainless Steel Laser Cutting Bending Auto Machine Part Auto Stamping Pars Sheet Metal Parts with Hot selling

Product Description

Customized Stamping Parts,ZheJiang Metal Stamping,China Manufacturer High Quality OEM Stamping Part

Feature of Stamping parts:

1.Precision Stamping parts strictly according to customers request drawing;

2.Tolerance:Could be in +/- 0.02mm;

3.Quality assurance in accordance with ISO9001;

4.Experienced technology engineers for 30 years & Well tranined workers;

5.Production line is very professional with the special process;

6.Fast and timely delivery:Speedly & Professional servie;

7.Stamping Series: Stamped part, guard board, precision metal stamping, pressing parts with powder coated, pressing and welding parts, pressing and streching parts, pressing parts with glanvized.

8.Porcessing: Stamping, punching, bending, welding, threading, grinding ,milling, machining, lathe,assembling etc.

Products Description:

| Item name | Metal Parts |

| Manufacturer | Merid Machinery with advanced technology,professional skill and experienced technicians to fit our customers requirements. |

| Material | Iron, Aluminum, Carbon Steel, Brass, Stainless steel |

| Design | Use the advanced CZPT design software |

| Surface Treatment | self-color, galvanized,polishing,Zinc, powder coating, painting, nickle, chrome, polish, e-coating |

| Price Term | FOB HangZhou |

| Delivery Time | 25-60 days based on the different products |

| Package | Caton,Wooden Case or as Required |

| Industry | Customized parts are used in Building,Automotive,Electrical,Machiner assembly,Furniture,Aoil field Equipments,Marine equipments,Agricultural Machines,Transportation Equipment,OEM/ODM Electronics……… |

The other products:

QC:

Company information:

HangZhou CZPT Machinery Co.,Ltd was established in HangZhou, China in 1983, with and area of 10,000 square feet. We are a professional top provider and industrial leader of full-service stamping, welding, machining, die castings and fabrication of metal components.The fields covers:

1.Automotive parts

2.Medical parts

3.Agricultural parts

4.Stock farming parts

5.Architectural parts

6.Industrial parts

7.Special Fields

8.Energy Industry

9.Telecommunication

10.Optical Semi-Conductor

11.Appliance

12.Lighting

13.Aerospace

Merid is equipped with the in-house capabilities of taking your project from design – tooling – prototype – production to finish, and the professional technical and production team could provide you the best solutions to ensure high quality and cost effective production of your products,

In 2008 Peter assumed responsibilities as President, still holding dear to his vision of embracing technology to ensure customer satisfaction. During the next 10 years, Peter continued looking at the product being made and researched othertypes of equipment to better manufacture the product we were providing our customers. The management team was also enhanced with other seasoned industry professionals.

Machinery work times per day:

| 220T Press Machine | 160T Press Machine | 80T Press Machine | 63T Press Machine | 35T Press Machine | |

| Work times per day | 6000 | 8,000 | 13,000 | 18,000 | 30,000 |

Market:

| Main Markets | Total Recenue(%) |

| Europe | 18 |

| America | 16 |

| Domestic Market | 13 |

| Eastern Asia | 12 |

| Mid East | 21 |

| Africa | 20 |

Package:

FAQ:

1.What are our advantages over others?

a). Stamping, Machining, Welding, Die casting and Surface treatment equipment are equipped for providing you our best service and solutions.

b). 45 years experience.

c). On-time delivery.

e). Strict Quality Control System: 100% inspection before the shipment.

.

2.What are the production capacity of your company?

a). In Merid, fabrication works include precision stamping, deep drawing, fine blanking, cnc punching, cnc bending, laser cutting, flame cutting, cnc milling, cnc turning, tube bending, aluminum extruding, welding, die casting, etc.

b). Metal materials include stainless steel, iron, carbon steel, spring steel, aluminum, titanium, copper, brass, bronze etc.

3.What equipments do you own?

a). Punch Press: 16T-400T.

b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.

c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).

d). Die casting: 80T-500T.

e). Surface treatment: Shot blasting facility, Polishing, Deburring.

4.What finishes can you provide?

The finishes which we could provide is powder coating, painting, galvanizing, baked enamel, anodizing finish, and other plating finishes.

5.How can you guarantee the quality?

Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.

Contact:

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Month |

| Type: | Cold Stamping |

| Processing Type: | Shaping Metal |

| Material: | Cast Iron |

| Mould: | Multistep Progressive Dies |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Agricultural Parts and How They Work

The term “agricultural parts” covers many different mechanical devices used in agriculture. Agricultural machinery includes power tools, tractors, and countless other farm implements. Aside from these, it also covers hand tools. Here are some common examples of agricultural parts. Read on to learn more. Below are some common parts and how they work. If you own a tractor, consider purchasing a new set of agricultural parts. Just-in-time delivery is an excellent option for a quick turnaround on parts and components.

Steel

Steel agricultural parts are used in the production of many types of agricultural machinery. They are used in tractors, combine harvesters, balers, mowers, and more. Because of the high wear resistance and tensile strength of steel, these parts require special properties. One such metal is CZPT. A short overview of this material is given below. To learn more about its benefits and application, read on. Here is a look at the qualities of CZPT.

Different steels are used for the housing of the Gearbox. Different manufacturers have different requirements. In addition to being lightweight and durable, steel agricultural parts must meet different material standards to perform their functions well. When choosing steel for your gearbox, keep these factors in mind. In addition to the weight and strength, you should also consider the type of gearbox. Gearbox housing is the first part that gets ruined in your tractor. If you buy a cheap steel housing, it will have poor quality.

Other benefits of steel include its resistance to chemical pesticides and its malleability. Steel also makes soil and dirt easier to wipe off. In addition to being corrosion-resistant, steel is also 100% recyclable. Its antimicrobial properties may also make it suitable for outdoor use. So, if you are looking for agricultural equipment parts, choose a steel farm machinery manufacturer. The benefits of steel agricultural parts are many. You can use them in the construction of various types of agricultural equipment.

Boron steel has many benefits in agricultural equipment. Boron steel is a good option for agricultural machinery parts, because of its high resistance to rust and corrosion. It is also very resistant to heat, which saves farmers a lot of time and money in replacing parts. In addition to its corrosion-resistant properties, boron steel also possesses great abrasion and heat resistance. It also is a good option for agricultural equipment that requires heavy loads.

Structural steel

Agricultural buildings made of structural steel are designed to hold livestock and agricultural equipment while remaining secure. These structures are lightweight and sturdy, offering a high level of thermal performance and insulation continuity. They are durable, sturdy, and rot/pest resistant, which makes them an excellent choice for many agricultural applications. Agricultural buildings made of structural steel can be easily customized, and you can choose from a variety of accessories, such as second-floor mezzanines, mansard systems, walk-through doors, and more. They can easily be altered to suit any renovation or change in business needs.

Today, high-strength steel is an excellent choice for structural parts in agricultural machinery. It allows agricultural equipment to withstand virtually any environmental condition, and its well-designed components increase reach and lifting capacity while maintaining strength and stability. As harvesters become more complex and cover more acres per hour, the need for reliable fabrication becomes increasingly more essential. In addition to harvesters, sprayers are a great example of tractors that make use of structural steel.

In addition to using structural steel for agricultural parts, agricultural tools are made from this metal, which reduces the construction time and waste by up to 30%. Many of these parts are made from structural steel, and a specialized company can provide you with the parts you need. For more information about industrial structural steel, please visit CZPT Fabricated Steel or visit their website. There are many advantages of using steel in agricultural parts.

In addition to the benefits of using structural steel in agricultural applications, agricultural equipment can be built using aluminum alloys and other lightweight metals. Aluminum alloys, for instance, are lighter than steel, which is a great benefit in terms of reducing the weight of farm machinery and soil. Additionally, aluminum alloys are harder than steel, which makes them the ideal choice for dust-filled environments. Further, agricultural equipment can be designed with composite materials and can be made of aluminum or manganese.

Torsional dampers

If you’re in the market for a new torsional damper, the best solution might be a bolt-on unit. These units are based on steel spring damper technology, which is also used in clutch disks. They are resistant to temperature-induced aging processes. ZF’s solution, DynaDamp, utilizes the same technology as its Dual Mass Flywheel. There are several different sizes available to match the horsepower output of your tractor.

New regulations for tractors have increased demand for torsion control and dampers. Agricultural equipment, such as tractors, is being forced to use cleaner engines to reduce emissions. A torsional damper prevents vibration from spreading throughout the transmission and the rest of the vehicle. These parts can also come in straight spring and arc spring designs. Those with straight springs are the most common, while arc springs are used in agricultural applications.

CZPT agricultural parts are designed to meet the technical demands of today’s tractors. Agricultural parts, such as clutch disks, require a high level of protection against torsional vibration. CZPT torsional dampers reduce vibration in the power train, protecting engine components and reducing operator fatigue. CZPT torsional dampers offer low cost and high-performance solutions that can handle any drivetrain application.

Voith CZPT torsional vibration dampers provide hydraulic damping for drive train vibrations and isolation. These units are maintenance-free and can protect against overloads and extend the service life of all components. The CZPT has three series – engine torques up to 3,700 Nm; vehicle-specific; and application-specific. For the ultimate in performance and dependability, Voith CZPT is the only choice.

Just-in-time delivery

Just-in-time delivery of agricultural parts has become a widely used practice throughout industries. In agricultural production, for example, inputs for implements were in trucks on the day of their delivery and would be delivered to the farm at precisely the right time. This process has become widespread, reducing the need for costly inventories and lowering production, storage, and purchase costs for end-users. Here are five examples of how it can help farmers and other businesses.

A typical tractor has over 1,700 components. Increasing competition among automakers has forced manufacturers to move toward just-in-time delivery of agricultural parts. However, this approach fails if a single part fails to deliver the desired results. Farmers have had problems with shaft breaks in their planters, for instance. By using just-in-time delivery, these dealers avoid the problems associated with a last-minute purchase and focus on making the equipment work properly.

A major challenge of this type of supply chain is predicting demand. While JIT delivery can significantly reduce costs, the difficulty of predicting demand is significant. Suppliers must be able to deliver parts in time, ensuring maximum profitability. Agricultural companies must ensure that their suppliers understand demand and have good relationships with their customers. In this way, the cost of inventory management is reduced. And a single, well-designed supply chain can reduce costs.

In order to implement just-in-time delivery, businesses must be able to identify what customers need and how quickly they can supply it. Without such a service, companies may face huge risks. They may have to sacrifice supply, certain products, or entire customer bases. These costs cannot be measured and are therefore unwelcome by many companies. However, JIT can help improve profitability and market share. A comprehensive logistics provider such as CZPT will provide operational procedures and resources for implementing JIT in a business.

Precision-based tech

Agricultural production is increasingly relying on technology for the benefit of farmers and their crops. The underlying science behind precision farming uses computer software and sensors to detect and improve soil conditions. With nearly 475 million farm households around the world, precision agriculture is important, as many of these operations are small and lack resources. The technology is also relevant to farms in developed countries that employ large production systems. However, implementing precision farming may be too expensive for small farms.

The goal of precision agriculture is to increase crop productivity and efficiency while protecting the environment. The use of technology helps farmers make better decisions on when to plant their crops, which can improve yield and quality, as well as cut greenhouse gas emissions. By incorporating precision technology into farming, farmers can use data from the field to plan for the future. Precision agriculture can be used in large and small fields. Precision farming can also help farmers monitor and optimize soil conditions and apply fertilizer at the proper time.

Agricultural equipment must be able to communicate with each other. With the help of machine learning and artificial intelligence, companies can process billions of data points and find meaningful patterns and drivers. This technology is particularly suited to precision agriculture, as data points from the field can include a wide range of environmental factors, including water levels and soil conditions. When smart computer algorithms analyze all this data, they can make intelligent recommendations on crop yield and quality.

Using precision technology for agricultural operations is essential for maximizing crop yield and quality. It can save time and money by optimizing irrigation systems, minimizing crop damage, and improving production. Precision technology can also help farmers reduce the amount of resources used to produce a particular crop. A small farmer can increase the output of a crop while minimizing waste and maximizing profits. With the use of these technologies, farming can be more productive and environmentally sustainable.

editor by CX 2023-11-08

China supplier Custom Q235 Steel Agricultural Machine stamping punching steel part agricultural sprayer parts suppliers

Issue: New

Warranty: 1.5 many years

Relevant Industries: Constructing Content Retailers, Production Plant, Farms

Showroom Area: None

Type: Shafts

Use: Cultivators

Following Guarantee Support: On-line support

Regional Service Location: None

Component identify: custom made metal stamp punching part

Software: Agriculture Machine Areas

Content: C45, Q345B,Q235

MOQ: 500 pcs

Deal: Standard Packaging

Principal marketplace: The us Canada Australia

Shade: Need

Feature: Outstanding Wear Resistance

Weight: 3.5 kg

OEM: Accepable

Packaging Information: Anti Rust Oil Wrapped Export picket package deal Water evidence wraaped

Port: China port

Customized Q235 Metal Modern Agricultural Machine stamping puching metal partSupplying personalized agriculture equipment spare components

custom-made all dimension as your necessity

CAD drawing confirmation

Materials:Q235,Gcr15,40CR, r collection 5hp torque r sequence inline helical gear motor coaxial reducer gearbox equipment motor 22kw reverse gearbox for motor electrical power Q345B,C45,copper, alloy,SUS440

Application:

automobile market wheel bearing hub

agriculture machine wheel bearing hub

agriculture machinery spare elements

Other excavator bushing areas

Major Attributes1) Substantial precision tolerance

two) entire approach QC

3) thread examining every single 1.

four) anti rust treatment, blacken area

Our Service Pre-Product sales Support* Inquiry and consulting assist. Blend Harvester Blades from Chinese Makers

* Sample testing help.

* See our Factory.

Huge inventory,please get in touch with us for inventory things.* MOQ little

* rapidly supply available

*Ready Supply Shipment.

Application Case in point

| Component title | Agriculture machinery spare elements |

| Merchandise Kind | customized Q235 steel cap upside and down facet set |

| Fitting equipment | agriculture equipment, agriculture harvest equipment, Custom Created Sand Casting Solutions Agricultural Machinery Components |

| Feather | powerful keeping ability |

| Shade | First steel colour,custom made portray by them selves. |

Quality controal Tensile screening machineTensile screening equipment to chcke Completed product tensile price

Chemical analysisCheck ram content chemical composition Hardness check deviceRaw material, warmth dealt with merchandise

completed solution all examine

Packing & Shipping wheel bearing hub packing style Single plastic bag packed

export wood package

water proof film wrapped.

Export wooden packagesteel belt wrapped external

pallet dimensions:L*W*H 1100*1000*850MMPallet weight:1.~1.2T

Wheel hub bearing packing style 2single box if customer requst

industrial pack

ten~20pcs in 1 cartons

36 cartons 1 pallet

pallet dimensions:L*W*H 1100*a thousand*850MM

Pallet fat:1.0T

Related Merchandise Products Laptopninety one.8% Reaction Price

Items EX20091.8% Response Price

Chrome metal flange bushingninety one.8% Response Price

Bushing Application, Type and Compression Capability

Bushings are cylindrical bushings used in machinery. It prevents wear of moving parts and is often used as an enclosure. Bushings are also known as plain bearings or sleeve bearings. You may be wondering what these parts do and how they work, but this article aims to answer all your questions. We’ll cover bushing applications, types and compression capabilities so you can choose the right one for your needs.

application

A bushing is a mechanical component that plays an important role in many different fields. In addition to being very practical, it helps reduce noise, vibration, wear and provides anti-corrosion properties. These properties help mechanical equipment in various ways, including making it easier to maintain and reducing its overall structure. The functionality of an enclosure depends on its purpose and environment. This article will discuss some of the most common applications of casing.

For example, in an aircraft, the bushing assembly 16 may be used for the bulkhead isolator 40 . The bushing assembly 16 provides the interfaces and paths required for current flow. In this manner, the sleeve assembly provides a secure, reliable connection between two objects with different electrical charges. They also prevent sparking by increasing the electrical conductivity of the component and reducing its resistivity, thereby minimizing the chance of spark formation.

Another common application for bushings is as a support shaft. Unlike bearings, bushings operate by sliding between two moving surfaces. As a result, they reduce friction and handling stress, reducing overall maintenance costs. Typically, the bushing is made of brass or bronze. The benefits of bushings are similar to those of bearings. They help extend the life of rotating machines by reducing frictional energy loss and wear.

In addition to identifying growth opportunities and minimizing risks, the Bushing Anti-Vibration Mounts Market report provides insights into the dynamics of the industry and its key players. The report covers global market size, applications, growth prospects, challenges and regional forecasts. The detailed section on Bushing Anti-Vibration Mounts industry provides insights on demand and supply along with competitive analysis at regional and country level.

type

There are several types of bushings. Among them, the SF6 insulating sleeve has the simplest structure and is based on composite hollow insulators. It also has several metal shielding cylinders for regulating the electric field within the enclosure and another for grounding the metal shield. In addition to being lightweight, this sleeve is also very durable, but the diameter of its shield electrode is very large, which means special installation and handling procedures are required.

Linear bushings are usually pressed into the bore of the shaft and provide support as the shaft moves in/out. Non-press-fit bushings are held in place by snap rings or pins. For certain applications, engineers often choose bushings over bearings and vice versa. That’s why. Below are some common bushing types. If you need to buy, make sure you know how to tell them apart.

OIP bushings are used for oil-filled cable boxes, and oil-to-oil bushings are used for EHV power transformers. The main components of the OIP enclosure are shown in Figure 7a. If you are considering this type of bushing for your specific application, you need to make sure you understand your specific requirements. You can also consult your local engineering department for more information.

All types of bushings should be tested for IR and capacitance. The test tap should be securely attached to the bushing flange. If damaged bushings are found, replace them immediately. Be sure to keep complete records of the enclosure for routine maintenance and any IR testing. Also, be sure to pay attention to tan d and thermal vision measurements.

Compressive ability

There are several things to consider when choosing an enclosure. First, the material. There are two main types of bushings: those made of filled Teflon and those made of polyester resin. The former has the highest compressive strength, while the latter has a lower compressive capacity. If you need small amounts, glass-filled nylon bushings are the most common and best option. Glass-filled nylon is an economical material with a compressive strength of 36,000 lbs.

Second, the material used for the enclosure must be able to withstand the load. For example, bronze bushings can cause metal shavings to fall into the papermaking process. CG materials can withstand very high levels of moisture, which can damage bushings that require lubrication. Additionally, these materials can operate for extended periods of time without lubrication. This is particularly advantageous in the paper industry, since the casing operates in a humid environment.

In addition to the material and its composition, other characteristics of the enclosure must also be considered, including its operating temperature. Although frictional heat from moving loads and the temperature of the bushing itself can affect the performance of the bushing, these factors determine its service life. For high temperature applications, the PV of the enclosure should be kept low. On the other hand, plastic bushings are generally less heat resistant than metal bushings. In addition, plastic sleeves have a high rate of thermal expansion. To avoid this, size control is also important.

Low pressure bushings have different requirements. An 800 MVA installation requires a low voltage bushing rated at 14 000 A. The palm assembly of the transformer also features a large central copper cylinder for electrical current. The bushing must withstand this amount of current and must maintain an even distribution of current in the transformer tank. If there is a leak, the bushing must be able to resist the leak so as not to damage the transformer.

cost

The cost of new control arm bushings varies widely. Some parts are cheaper than others, and a new part is only $200. However, if you replace the four control bushings in your car, the cost can exceed $1,200. The cost breakdown for each section is listed below. If you plan to replace all four, the cost of each bushing may range from $200 to $500.

The control arm bushing bears the brunt of the forces generated by the tire and is parallel to the direction of the force. However, over time, these components wear out and need to be replaced. Replacing one control arm bushing costs between $300 and $1,200. However, the cost of replacing each arm bushing depends on your car model and driving habits. The control arm bushings should last about 100,000 miles before needing replacement.

The repair process for control arm bushings is time consuming and expensive. Also, they may need to remove the heat shield or bracket. In either case, the procedure is simple. Stabilizer bar brackets are usually attached with one or two mounting bolts. They can also be secured with nuts or threaded holes. All you need is a wrench to remove them.

The control arm bushings are made of two metal cylinders and a thick rubber bushing. These parts can deteriorate from potholes, off-roading or accidents. Because they are made of rubber, the parts are more expensive than new. Buying used ones can save you money because you don’t need to install them yourself. However, if you do plan on fixing a luxury car yourself, be sure to find one that has a warranty and warranty.

maintain

To prevent your vehicle from overheating and leaking oil, a properly functioning bushing must be used. If the oil level is too low, you will need to check the mounting bolts to make sure they are properly tightened. Check gasket to ensure proper compression is applied, replace bushing if necessary. You should notify your vehicle manufacturer if your vehicle is immersed in oil. Whenever an oil leak occurs, it is very important to replace the oil-filled bushing.

Another important aspect of bushing maintenance is the detection and correction of partial discharges. Partial discharge is caused by current entering the bushing. Partial discharge can cause tree-like structures, cracks and carbonization in the discharge channel, which can eventually damage the casing. Early detection of these processes is critical to ensuring that your vehicle’s bushings are properly maintained. Identifying and repairing partial discharges is critical to ensuring optimal operation, regardless of the type of pump or motor.

To diagnose casing condition, perform several tests. You can use tan d measurement, which is a powerful tool for detecting the ingress of water and moisture. You can also use power factor measurements to detect localized defects and aging effects. You can also check the oil level by performing an infrared check. After completing these tests, you will be able to determine if there is enough oil in the casing.

If the oil level in the transformer is too low, water and air may leak into the transformer. To avoid this problem, be sure to check the MOG and transformer oil levels. If the silicone is pink, replace it. You should also check the function of the oil pump, fan and control circuits annually. Check the physical condition of the pump and fan and whether they need to be replaced. Clean the transformer bushing with a soft cotton cloth and inspect for cracks.

China supplier China Manufacture OEM Aluminum Brass Stainless Steel CNC Machining Parts for Sewing Agricultural Machinery Coffee Machine with Good quality

Product Description

Product display

Product description:

1-material:

Stainless steel:SS201,SS301,SS303,SS304,SS316,SS416 etc.

Iron:A36,45#,1213,12L14,1215 etc.

Aluminun:AL6061,AL6063,AL6082,AL7075,AL5052 etc.

Copper:C11000,C12000,C36000 etc.

Brass:HPb63,HPb62,HPb61,HPb59,H59,H62,H68,H80 etc.

Steel:mild steel,carbon steel,4140,4340,Q235,Q345B,20#,45# etc.

Plastic:ABS,PP,PEI,Peek,PE,POM,Delrin,Nylon,Teflon etc.

2-Parameter

3/4/5-axis CNCmilling,CNC Turning,dilling etc.

Precision:CNC turning ±0.003mm,CNC Milling ±0.01mm

Test equipment:Project,CMM,Altimeter,Micrometer,Thread Gages,Calipers,Pin Gauge etc.

Drawing Format:IGS,STP,X-T,DXF,Pro/E,PDFA

Workable size: CNC turning :φ0.5-φ300*750mm,CNC milling:510*1571*500mm(max).

3-Finishing:Chrome plating,Nickle plating,Tin plating,Zinc plating,Polishing,Anodizing,Power-coating,Oxide black.electroless nickel etc.

4-OEM&ODM are welcome.welcome to processing by drawing and sample.we have powerful equipment to support the processing of products.The main equipment:Machining Center,CNC,Lathe,Turning machine,Milling machine,Drilling machine,Internal and external grinding machine,Cylindrical grinding machine,Tapping drilling machine,Wire cutting machine etc.

5-Delivery time:5-25days after the confirmation of sample(according to order quatity.)

The mode of transportation:Express,by sea or by air(according to customer needs)

Parking:carton/wooden box/other

12 years more experienced engineers team and well trained sales team to support every project.We need long-term customers,excellent products quality and competitive price are our basic to achieve it.

why choose us?because we are professional.Place your order and we’ll take care of the rest.

Thank you.

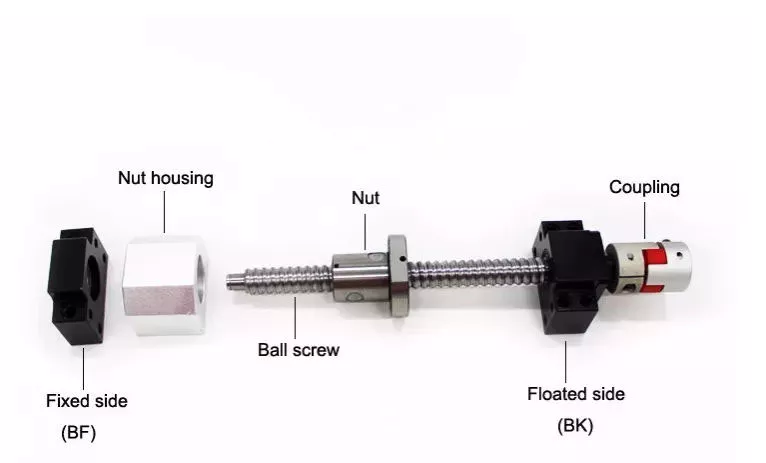

Advantages of Ball Screws and How They Can Benefit Your Applications

When selecting a ball screw for your application, there are several factors to consider. This article will discuss high mechanical efficiency, low friction, multiple repair options, and application requirements. Choosing the right ball screw can help you get the job done quickly and effectively. To make your decision easier, consider the following tips. Read on to learn about some of the advantages of ball screws and how they can benefit your applications. Here are some of the most common types:

High mechanical efficiency

The mechanical efficiency of ball screws can be measured using the axial load test. The axial load is equal to 0.5 x FPr / 2Fpr. The elastic deformations are measured as DL1 and DL2, respectively. Common engineering procedures work at 90 percent reliability; however, certain sectors require higher reliability, which has a direct impact on the dynamic load capacity. The axial load test is 1 of the most widely used methods to determine the mechanical efficiency of ball screws.

In order to achieve high translation, ball screws must be designed with high stiffness and positioning accuracy. In addition, high preloads increase the initial driving torque and cause more friction and heat. Other important design criteria include low driving torque and reduced slip motion. This means that the high translation capacity of ball screws must be well matched to the overall application. The following are some common design criteria for ball screws. You can select the best type of ball screw for your needs.

The high mechanical efficiency of ball screw is achieved by avoiding the common sag and pitch problem. The ball track design helps to reduce the centrifugal force. The ball screw’s diameter can be adjusted by adjusting the centre pitch of the nut on 2 ball tracks. The nut’s axial load is also adjusted through the offset centre pitch. This method allows the users to increase the mechanical efficiency of ball screw by up to 40%.

When calculating the mechanical efficiency of ball screw, consider the application’s environment, speed, and other factors. If the application requires precision and accuracy, then the ball screw is the right choice. The engineering department of a ball screw manufacturer will carefully review the application factors and come up with a design that meets the application’s expectations. Moreover, some manufacturers even offer customized ball screws, which can be tailored to your requirements.

Low friction

The operating performance of a low-friction ball screw is characterized by its minimal friction. This screw has a structure that transmits forces through rolling steel balls. The torque is calculated by calculating the load and the lead screw’s dimensions. This type of screw can be used for a variety of different applications, including hydraulic systems. Read on to learn more about this type of screw and how it can help you build a more reliable and durable car.

The critical speed of a ball screw is higher than that of a lead screw, so this type of screw can accommodate larger loads and speeds. It also has a lower friction coefficient, which reduces the amount of heat produced. High-quality ball screws can withstand longer duty cycles than standard lead screws. However, in order to compare the two, you must take into account the duty cycle. Low-friction ball screws are more durable than lead screws, and the duty cycle is only 1 of the factors you should consider when selecting them.

The ball bearings are the most prominent component of a low-friction ball screw. Their main function is to reduce the friction between the nut and the shaft. Without them, the friction would be too high. This feature is possible thanks to the ball bearing’s groove profile. Two arcs intersect at the contact points on the shaft and nut. Consequently, the ball bearing reduces friction in a way that is essentially non-existent without the bearing.

The mechanical efficiency of a low-friction ball screw is very high. The typical ball screw is up to 90% efficient, but some types can reach a higher efficiency. They are commonly used in machine slides, presses, and linear actuators. The high efficiency of a low-friction ball screw makes it a great choice for many different applications. This type of screw is made of several main components. The ball bearings provide the helical raceway for the ball assembly and threaded shaft is the screw part. The ball screw is comparatively more bulky than a conventional leadscrew, but the overall size is smaller than its lead counterpart.

Multiple repair options

A damaged ball screw will typically display visible physical signs, including noise or vibration. Additionally, worn ball screws will require more horsepower and torque to operate. They may also cause lead accuracy issues. Luckily, there are multiple repair options for ball screws. You can get new ball screws to restore preload and reduce backlash. But there are some warning signs to look out for first. Keeping a close eye on your ball screw’s health can help you avoid a costly replacement.

Look for a ball screw repair company with a proven track record of servicing all types of ball screws. The service should offer a free evaluation and 3 types of service: reload, recondition, and replacement. Reload is the simplest option and involves cleaning and polishing the screw and ball nut. Reconditioning or replacement, on the other hand, requires new parts. Choose the 1 that offers the best value for your money.

EP offers an emergency service and superior service for your ball screws. Their UK service includes delivery and international shipping. All ballscrew repairs are covered by a full service warranty, and the company is known for providing competitive pricing. If you do need a ball screw repair, look no further. Contact K+S today to discuss your specific needs. You’ll be glad you did. You’ll save up to 70% over purchasing a new ball screw.

While ball screw repair is an easy and inexpensive option, it may be necessary to have it replaced more frequently than the usual. In addition to replacing worn ball screws, you may need to consider a different type of repair. This process involves grinding the ball nut and journal diameters back to their original size. Fortunately, level 4 is the most expensive but can restore a screw’s lifespan. This is also the most extensive type of repair available for a ball screw.

Application requirements

A ball screw is an efficient solution for precision motion control in many applications, including automotive and aerospace. These screw-type devices are highly resistant to corrosion, and the alternating steel-ceramic architecture ensures extreme reliability and sturdiness. For the aerospace sector, a ball screw replaces the typical hydraulic system, and the product is used in wind turbine blade pitch and directional position, solar panel movement, and gate control in hydroelectric stations. Ball screws are also used in motorised inspection tables, step photolithography machines, microscopic integrated circuits, and many other applications.

The most critical requirements for a ball screw assembly are backlash and bearing support. Backlash is the amount of axial motion between the screw and nut, which leads to positioning errors. Although this axial motion is minimal, it can be as little as 70um. If the preload is too large, a ball screw may suffer from excessive heat. Depending on the application, the amount of preload required can be adjusted to maximize the overall performance of the device.

The choice of screw is determined by the load capacity. For example, plastic nuts are commonly used for light loads, while bronze nuts are used for loads that weigh several thousand pounds. Lead screws are not particularly reliable in situations where load requirements are extremely high, and a ball screw will often be a better option. The lower friction of a ball screw allows it to withstand higher duty cycles than a lead screw. When the load requirements exceed lead screws’ capacity, a ball screw is the better choice.

A step photolithography machine is another example of an application where ball screws play an important role. This device helps manufacturers produce microscopic integrated circuits by harnessing the reaction of light. A stepper is a critical piece of this machine, as it controls the positioning of light exposure on the silicon wafer. High precision is required for this application. Ultimately, a ball screw will make the process easier. Its proven record for meeting instrumentation requirements is an excellent example of its value in the laboratory.

Cost

The global market for ball screws is growing at a steady pace, but what drives the growth? In the ball screw industry, performance, cost, and analytical predictability are the primary concerns of OEMs. This market study provides in-depth analysis of these market dynamics. You’ll learn how to best compete in the global market for ball screws. Here are some tips to help you get started:

Ensure you have a good grasp of the differences between lead and ball screws. The cost of lead screws depends on their efficiency, and some of them can achieve C5 level accuracy. However, ball screws are more durable and more repeatable. Besides, lead screws can’t achieve high precision because of their sliding motion, which gradually grinds away the accuracy. As a result, the cost of a ball screw is more than compensated by the improved performance of OEMs.

To get the best price for ball screw, look for a manufacturer with a strong technical force. Most of these manufacturers have sophisticated equipment and strict quality control systems. They draw inspiration from the requirements of the market and have continuously increased their technological content to stay ahead of the competition. If you’re in Pune, look for a manufacturer with this technology. It won’t be difficult to do business with such a supplier. The company will also provide you with contact information, including their office address and phone numbers.

When choosing between lead and ball screws, you need to understand how they work and why they’re more reliable. Ball screws are more durable than lead screws, which is 1 of the primary reasons for their popularity. Lead screws, on the other hand, are often used for vertical applications. Lead screws tend to be cheaper than ball screws, but they have more limitations. When used properly, however, they can increase the life and performance of machines. In general, they’re corrosion-resistant and offer great design flexibility.